|

Shenzhen Yuhan electro-mechanics Co., Ltd

|

jaw roll crusher /small diesel engine jaw crusher

| Payment Terms: | T/T,L/C;O/A |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1 Three Utility model patents.

2 Low price with high quality

3 Guarantee 2 years.

4 Stable performance

Structure and Operating Principle

The Jaw crusher machine is composed of Frame,Moving jaw,Eccentric shaft, Bearing,Dental plate,Toggle plate seat,Rull rod and Rod spring etc.The Frame is welded by Q235B steel plate and forepart is equipped with fixed dental plate,both sides have scaleboard to protect the frame from being abraded.Below the back there are rod spring linked to moving jaw to help the jaw back to steady.And on the top of the back have adjusting screw rod to adjust the size of discharge hole.

Application Jaw Crusher

Jaw Crusher is mainly used to crush kinds of mining stone primarily and the largest compression resistance of the material to be crushed is 320MPa. The jaw crusher is widely used in stone mining, metallurgy industry, building material, highway, railway, and chemical industry.

Quality and Service Jaw Crusher

1.The Wearing parts:

We use special materials for our spare parts, like Mn13, Cast Iron, Zinc Alloy etc, For example, the Movable jaw plate, the Fixed jaw plate, the side plate of Jaw crusher are made of Mn13, which is much wear resistance than normal materials. And their usage life is longer.

2. Quality.

We guarantee TWO YEARS for our quality. During the guarantee period, if any problem, we will check and repair it for our customer FREELY. If exceed the guarantee period, we will also check and responsible for our customers. What's more, if the crushing plant we recommended are not satisfied to our customer's requirements, we will change the suitable machine for our customer FREELY. This is our Quality policy.

3.After-sale services:

1. We will supply the most suitable crushing plant to customers according to their requirements.

2. Assist clients to prepre for the first construction scheme, we will supply the Machine Base drawing and Installation manual.

3. For the Installation, we will dispatch two or three engineers to guide the installation, take the trial test, train their worker, debug the equipment, adjust the capacity etc.

4. The regular inspection and maintenance will be supplied on time.

Main Technical Parameter

| Model | Feed Opening (mm×mm) | Max. Feed Size (mm) | Capacity (t/h) | Rotor Speed (rpm) | Motor Power (kW) | Discharge Opening (mm) | Weight (t) |

| PE-250×400 | 250×400 | 210 | 5~20 | 300 | 15 | 20-60 | 2.8 |

| PE-400×600 | 400×600 | 340 | 16-65 | 275 | 30 | 40-100 | 6.5 |

| PE-500×750 | 500×750 | 425 | 45-100 | 275 | 55 | 50-100 | 10.1 |

| PE-600×900 | 600×900 | 500 | 50-120 | 250 | 55-75 | 65-160 | 15.5 |

| PE-750×1060 | 750×1060 | 630 | 52-180 | 250 | 110 | 80-140 | 28 |

| PE-800×1060 | 800×1060 | 650 | 85-143 | 250 | 110 | 100-200 | 30 |

| PE-870×1060 | 870×1060 | 670 | 181-210 | 250 | 110 | 200-260 | 30.5 |

| PE-900×1200 | 900×1200 | 750 | 140-260 | 200 | 110 | 95-165 | 50 |

| PE-1000×1200 | 1000×1200 | 850 | 160-300 | 200 | 110 | 195-265 | 51 |

| PE-1200×1500 | 1200×1500 | 1020 | 300-600 | 180 | 160 | 150-300 | 100.9 |

| PEX-250×750 | 250×750 | 210 | 8~22 | 330 | 22 | 25-60 | 4.9 |

| PEX-250×1000 | 250×1000 | 210 | 16-52 | 330 | 30-37 | 25-60 | 6.5 |

| PEX-250×1200 | 250×1200 | 210 | 20-60 | 330 | 37 | 25-60 | 7.7 |

| PEX-350×1300 | 300×1300 | 250 | 20-90 | 330 | 55 | 20-90 | 11 |

We(Shenzhen Yuhan Electro-Mechanic Co.,Ltd)are pleased to introduce you ourselves as one of the leading and well established/Manufacturing and Supplying of High Quality Products as below main items:

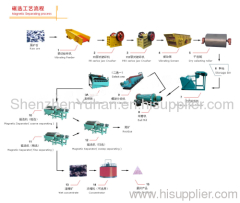

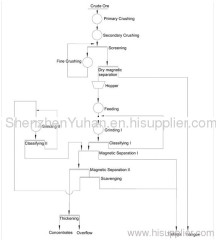

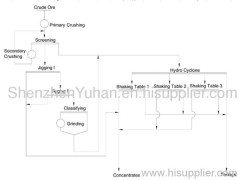

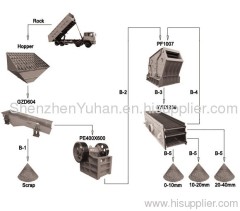

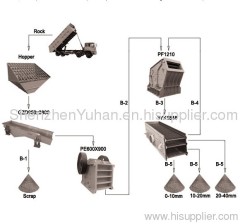

Stone production line:

Including:

Jaw crusher

Cone crusher

Hammer crusher

Vibrating screen etc

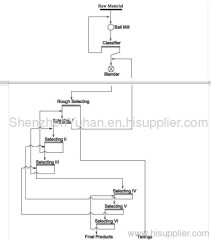

Sand making production line:

Including:

Sand making machine (VSI crusher)

Sand washing machine

Vibrating screen etc

We have a perfect after-sales service system and team with professional after-sales service has provided customers with prompt and thorough service. Our price are most competitive and reasonable, all order will be supplied within the stipulated period. Awaiting your first inquiry order.