|

Shenzhen Yuhan electro-mechanics Co., Ltd

|

Gold Index: 17787

You are here: home > mining/crushing production line > gravity method copper ore beneficiation plant

gravity method copper ore beneficiation plant

| Payment Terms: | T/T,L/C |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Means of Transport:

Ocean,Land

Packing:

normal packing

Application:

Ore

Production Capacity:

200 sets/month

Delivery Date:

20 days

Type:

Others

copper ore beneficiation plant

1.have 36 years manufacture experience

2.exported to over 30 countries

3.certificate ;ISO SG

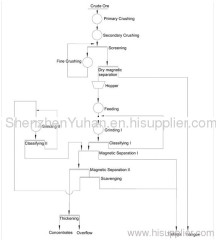

(1) disseminated copper ore flotation

Generally use relatively simple process in the copper ore beneficiation plant, through a grinding fineness-200 mesh about 50% to 70%, 1 roughing,2 or 3 times selected, 1 or 2 times sweep the election. Comparison of disseminated copper minerals, such as samll size, may consider the stage of grinding and separatino process. Treatment spot copper concentrator, mostly coarse concentrate regrinding-a selection of stage grinding and separation proceses, and its essence is mixed-flotation process. First through a coarse grinding, roughing, saving jaw crusher and then rough concentrate. Coarse Ground degrees-200 mesh about 90% to 95%.

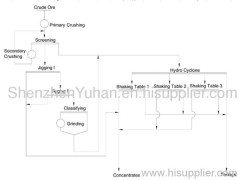

(2)dense compact copper ore copper ore flotation machine chalcopyrite and pyrite as tight symbiosis, pyrite is often of secondary copper-activated pyrite content is high, difficult to inhibit the separation difficult.

Sorting process required by copper concentrate and concentrate at the same time. Usually after the election of copper tailings is pyrite concentrate. If the ore gangue content of more the 20% to 25%, sulfur concentrate needed to get re-sorting ball mill. Densse copper ore processing, often using two stages of grinding or grinding, girinding fineness requirements smaller. Als larger amount of reagent, xanthate dosage 100g(t ore), lime 8-10kg(t ore) above.

Technical Parameters of Flotation Cell in the copper ore beneficiation plant

Model | Cell Volume (m³) | Impeller Diameter (mm) | Productive Capacity (m³/min) | Impeller Rotational (r/min) | Motor of Impeller | Motor of Scraper | Overall Dimension of Four Cells (mm) | Weight Of Single Cell (kg) | ||

Model | Power (KW) | Model | Power (KW) | |||||||

XJK-1A | 0.13 | 200 | 0.05~0.16 | 593 | Y90L-4 | 1.5 | Y802-4 | 0.75 | 500*500*550 | 266 |

XJK-2 A | 0.23 | 250 | 0.12~0.28 | 504 | Y100L-4 | 1.5 | Y802-4 | 0.75 | 600*600*650 | 389 |

XJK-3 A | 0.35 | 300 | 0.15~0.5 | 500 | Y90L-4 | 1.5 | Y802-4 | 0.75 | 700*700*700 | 430 |

XJK-4 A | 0.62 | 350 | 0.3~0.9 | 400 | Y132S-6 | 3 | Y90L-6 | 1.1 | 900*900*850 | 630 |

XJK-5 A | 1.1 | 500 | 0.6~1.6 | 330 | Y132M-6 | 5.5 | Y90L-6 | 1.1 | 1100*1100*1100 | 1300 |

XJK-6 A | 2.8 | 600 | 1.5~3.5 | 280 | Y160L-6 | 11 | Y100L-6 | 1.5 | 1750*1600*1100 | 2325 |

Welcome to our factory ,we will do our best to meet your requirement

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Shenzhen Yuhan electro-mechanics Co., Ltd [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)

You May Like:

Product (299)

- Coal Mill/Ball Mill (10)

- generator (55)

- Beneficiation Equipment (41)

- mining/crushing production line (88)

- bus (36)

- mining machine (68)

- Others (1)